Dune House Bergen aan Zee

- Commission The Dune House is the architect 's home

- Commissionar Jetty and Maarten Min

- Building company under own management

- Realisation 2010

- Adress Zeeweg 11, Bergen aan Zee

Dune House Bergen aan Zee

The owners of the office designed their own house in the dune area of Bergen aan Zee (NH).

An important design topic was to connect the form and the materialization of the house with the place where it is situated.

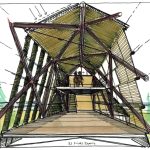

Design

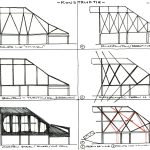

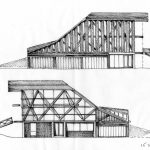

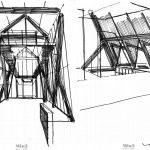

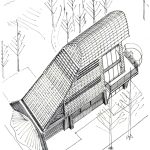

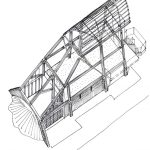

The building enjoys a dominant position on a dune crest. They therefore have chosen for a strong “object-quality”. Handling the building plan as a starting point within the zoning plan and the existing building regulations was also a challenge. The admissible constructing surface was 20 x 8 meters, with a gutter height of 3 meters. The ridge height was not indicated and therefore a ridge height of max. 15 meters was possible. These proportions made it possible to build the house vertically, an opportunity achieved by realizing three high storey. One of the main concerns was that, in its appearance, the high tall form had to fit in the dune landscape. During the design process this form became one of a dune or of a windswept group of trees sloping along with the worn landscape near the sea. The openings in the roof surface of the storey were designed from within: at the sea side as horizontal window strips and at the dune side as a huge window, where it is possible to imagine oneself in the midst of the dune landscape. The flat facade on the eastside eventually allows for a lift and balconies.

Materialization and low-tech

For quite some time they have been looking for the appropriate materials on the outside. Because the house is only 300 meters from the sea, they took the logical decision to choose for natural, sustainable and low maintenance materials. They called this a low-tech approach.

For the oblique façade- and roof skin they thoroughly searched for an existing material that would fit into the rough romantic scenery. In the end, Jetty came up with the idea to design herself a tile that would fit the desired agenda. Following the remarkable Kolumba brick (Petersen Tegl) which was to be used for the dressing of concrete columns, a long ceramic flat tile was developed of 53 centimeters long, 17 centimeters high and 4 centimeters thick. These tiles give the impression of pot lid shelves, but ones which are much more low maintenance. The brown/purple appearance of the British clay with its rough finish has to visually match the bark of the surrounding firs. Thanks to all these characteristics, the building now perfectly fits into its surrounding environment.

This developing process took one and a half year. It has also been helped by the excellent cooperation of the professionals of Petersen Tegl. The tile has now been included in the collection of Petersen and used in several buildings in Europe.

The finishing of the eaves has been carried out in zinc and has been pre-treated against ionization, which beautifully matches the tiles. The untreated wooden frames are made of Iroko, FSC approved and carefully handpicked to have the longest parts, in order to avoid gluing as much as possible. The reason to make use of untreated wood at this location stems from its low maintenance aspect, which also fits into the natural surroundings.

Where, if necessary, a lift can be build, the concrete stabilization drives have been closed with untreated western red cedar parts.

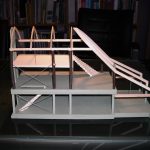

The building façade has a timber frame with a high insulation value. Because of this starting point they could easily design the bent and beveled forms as a basis. The basis of these elements consists of whitewood collar beams with multiplex sheets. These are built in several prefab parts, made in the workshop, for a smooth progression of the building process and to generate as less disturbance in the protected green area as possible.